In this beginners guide to 3d printing we will walk you through each step of setting up your FDM 3d printer, helping you get the most out of it with the least amount of trouble.

If you are looking for a beginners guide to 3D printing for SLA printer click here for our guide on SLA printers.

In this beginners guide to 3d printing.

Step 1: unboxing and Setup

- Unbox the 3D Printer:

- Carefully remove the printer from its packaging.

- Check for all included components (printer, power cable, USB cable, SD card, filament spool, tools).

- Assemble the Printer:

- Follow the manufacturer’s instructions for assembly.

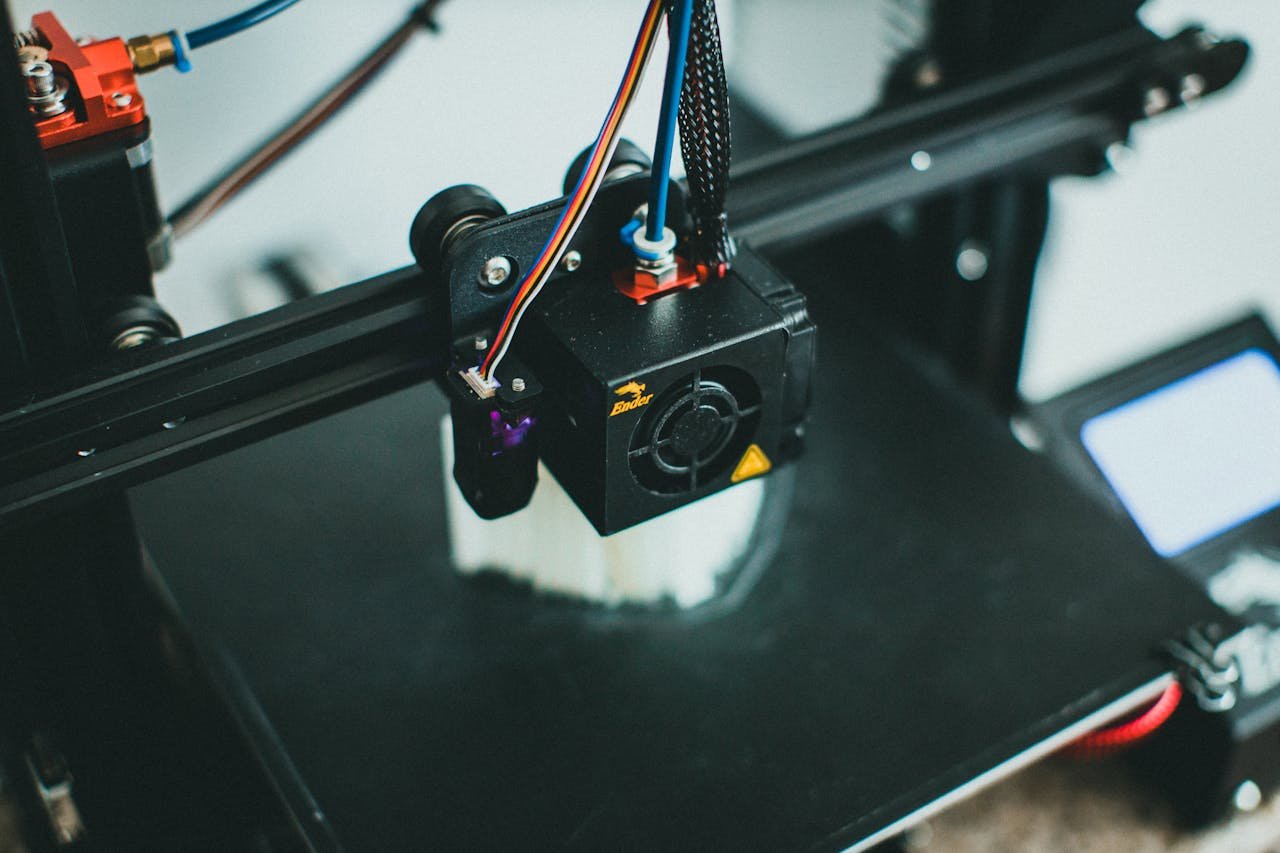

- This typically involves attaching the frame, connecting the extruder, and setting up the build platform. If you have purchased a preassembled printer like the Bambu Lab P1S there’s no need to worry about assembling anything.

- Level the Bed:

- Manually adjust the build platform to ensure it is level. Some printers have an auto configuration cycle that will prep the bed and set the printer up automatically for you this can take on average between 8-10 mins.

- If you do need to do it manually use a piece of paper or the manufacturer usually supplies a piece of slightly thicker gloss paper to check the gap between the nozzle and the bed. The paper should slide with slight resistance.

Step 2: Preparing the Printer

- Load the Filament:

- Preheat the extruder to the recommended temperature for your filament.

- Insert the filament into the extruder until it starts to come out of the nozzle. Then stop the extruder and let it cool down.

- Install the Printing Software:

- Download and install slicing software (e.g., Cura, PrusaSlicer) on your computer.

- There are other slicing softwares which are more capable these are your standard slicers provided by the manufacturers. we recommend slicers like Simplify 3D we recommend them because even though you have to purchase this software it allows much more customisation of the printers settings and can massively help improve your success rate for 3d prints being successful. The ability to slow down the first layers print speed and to reduce the layer height of this first layer helps the adhesion to the print bed immensely making for a much higher success rate. You can check out our review of Simplify 3D to see more on why we recommend them.

Step 3: Preparing the Print

- Find a 3D Model:

- Download a 3D model file (STL) from a online library like Thingiverse or MyMiniFactory.

- Or you can make your own model using Fusion 360 this software is designed for making components like a go pro mounting bracket or prototype gadgets, or if you more imaginative and want to create your own miniatures or characters have a look at blender. This software allows for some amazing creations with incredible details like scales or feathers.

- Slice the Model:

- Open the STL file in your chosen slicing software.

- Adjust print settings (layer height, infill density, print speed). If needed but when starting out I would go with the one of preset settings there should be an option for fast medium or slow these represent high quality being the slower setting medium quality and low quality being the fastest preset.

- Slice the model to generate G-code, which is the file format your printer reads.

- Save the G-code:

- Save the G-code file to an SD card or send it directly to the printer via USB.

Step 4: Printing

- Start the Print:

- Insert the SD card into the printer or connect via USB.

- Select the G-code file from the printer’s menu and start the print.

- Monitor the First Layers:

- Watch the printer as it lays down the first few layers to ensure proper adhesion to the build platform.

- Adjust settings if necessary (e.g., bed leveling, nozzle height).

Step 5: Post-Processing

- Remove the Print:

- Wait for the print to cool down.

- Gently remove the print from the build platform using a spatula or scraper.

- Clean Up:

- Remove any support structures or excess material.

- Sand or smooth the print if desired.

Tips and Troubleshooting

- Common Issues:

- If the print doesn’t stick to the bed, try re-leveling the bed, cleaning it, or using an adhesive (like glue stick or blue painter’s tape).

- If the print has gaps or is stringy, adjust the print temperature and retraction settings.

- Maintenance:

- Regularly clean the nozzle and bed.

- Check for loose screws and ensure belts are tight.

Additional Resources

- Online Communities:

- Join forums and groups (e.g., Reddit’s r/3Dprinting) for tips, support, and inspiration.

- Tutorial Videos:

- Watch YouTube tutorials for visual guides on setup, slicing, and troubleshooting.

By following these steps, you’ll be well on your way to creating your first successful 3D print. Happy printing!